Medical polymers

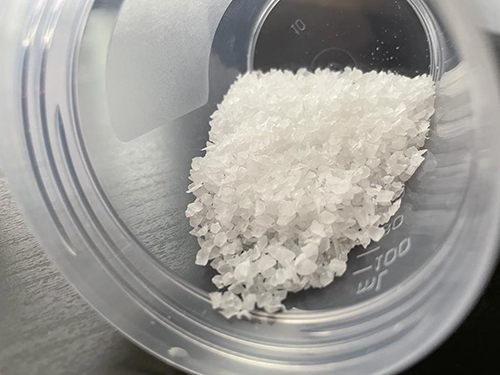

Biodegradable medical polymers meet international quality standards for use in medicine and pharmaceuticals.

We will help you choose the optimal polymer for solving your problem, which has the necessary characteristics:

✔ composition (L-lactide, DL-lactide, glycolide, e-caprolactone, trimethylene carbonate)

✔ molecular weight (from 1,000 to 500,000 Da)

✔ end groups (hydroxy-, carboxy-, ether, functional)

Polymers for medical devices and dosage forms

Biodegradable polymers are high molecular weight compounds that are used to make temporary implantable medical devices. After performing its function, the material degrades inside the body into safe products.

We offer a wide range of medical polymers based on cyclic esters with different compositions, molecular weights (from 1 to 500 kDa) and types of end groups.

We offer a wide range of medical polymers based on cyclic esters with different compositions, molecular weights (from 1 to 500 kDa) and types of end groups.

Polylactide (PLLA, PDLLA)

Biodegradable, biocompatible thermoplastic aliphatic polyester, the monomer of which is a cyclic dimer of lactic acid (L- or D,L-lactide). The starting materials for the production of lactic acid are annually renewable resources such as corn and sugar cane. The properties and supramolecular structure of polylactide change over a wide range when the content of L- and D-form lactic acid units in the polymer composition changes.

Main characteristics

Main characteristics- L/D ratio: 100/0, 50/50, 70/30, 0/100

- Degradation period: from 6 months. up to 5 years

- Glass transition temperature: 45 - 60 °C

- Melting point: 150 - 200 °C

- Young's modulus: 1.5 - 4 GPa

- Strength: 40 - 60 MPa

- Deformability: 1 - 10%

Areas of application

Areas of application- Vascular implants

- Products for traumatology

- Cosmetology products

- Long-acting dosage forms

- Regenerative medicine

Polyglycolide (PGA) and poly(glycolide-co-L-lactide) (PGLA)

Polyglycolide (PGA) and poly(glycolide-co-L-lactide) (PGLA) have high physical and mechanical characteristics and a controlled degradation period. They are widely used to produce fibers, threads and various medical devices for surgery.

Main characteristics

Main characteristics- Glycolide/L-lactide ratio: 100/0, 90/10, 15/85

- Degradation period: from 2 to 12 months.

- Glass transition temperature: 35 - 50 °C

- Melting point: 180 - 230 °C

- Young's modulus: 3 - 7 GPa

- Strength: 50 - 100 MPa

- Deformability: 1 - 10%

Areas of application

Areas of application- Surgical sutures

- Fibers, meshes

Poly(D,L-lactide-co-glycolide) (PLGA)

Random copolymers of D,L-lactide with glycolide (PLGA) are characterized by good solubility and short degradation time; they are mainly used to create nano- and microsomal dosage forms and sustained-release coatings. The release kinetics of the active agent can be tuned by changing the composition and molecular weight of the polymer.

Main characteristics

Main characteristics- D,L-lactide/glycolide ratio: 85/15, 75:25, 50:50

- Degradation period: from 1 to 6 months.

- Glass transition temperature: 40 - 50 °C

- Young's modulus: 1 - 2 GPa

- Strength: 30 - 40 MPa

- Deformability: 1 - 10%

Areas of application

Areas of application- Dosage forms of prolonged and targeted action

- Nanoparticles, microparticles

- Drug coatings on implants

- Regenerative medicine

Poly(ɛ-caprolactone) (PCL)

Poly(ɛ-caprolactone) is a partially crystalline biodegradable polymer produced by the polymerization of ɛ-caprolactone. It has a low melting point and high deformability.

Main characteristics

Main characteristics- Degradation period: 3 - 4 years

- Glass transition temperature: -60 °C

- Melting point: 60 - 65 °C

- Young's modulus: 0.2 - 0.4 GPa

- Strength: 20 - 40 MPa

- Deformability: 300 - 1000%

Areas of application

Areas of application- Vascular implants

- Fibers, surgical threads

- Cosmetical tools

- Long-acting medications

- Regenerative medicine

Poly(L-lactide-co-ɛ-caprolactone) (PLCL)

Copolymers of L-lactide with ɛ-caprolactone are characterized by increased deformability compared to polylactide and also demonstrate faster degradation. The decomposition period and physical and mechanical characteristics are determined by the ratio of L-lactide/ɛ-caprolactone in the copolymer.

Main characteristics

Main characteristics- L-lactide/ɛ-caprolactone ratio: 90/10, 75/25, 50/50

- Degradation period: from 3 to 18 months.

- Glass transition temperature: 20 to 50 °C

- Melting point: 120 to 180 °C

- Young's modulus: 0.3 - 1.5 GPa

- Strength: 20 - 50 MPa

- Deformability: 30 - 1000%

Areas of application

Areas of application- Vascular implants

- Products for traumatology

- Cosmetical tools

- Regenerative medicine

Custom polymer synthesis

We can synthesize a polymer according to the customer’s technical specifications, with a precisely specified composition, molecular weight, modified end groups, special architecture, etc.

We use cookies for the best possible presentation of our website. The purposes for using cookies are defined in the Company's Personal Data Processing Policy. If you agree to continue to receive cookies, please click the "Accept" button